Your Full-Service Distributor for Commercial & Industrial Laundry

The Local Service You Know is Now Backed by a Global Leader in the South

Introducing Alliance Laundry Systems Distribution

There’s no match for local service. And when you combine it with the experience of the nationwide leader in laundry equipment, you’ve got an unstoppable team. We’re your full-service partner for commercial laundry equipment—Houston and Dallas, Texas; Atlanta, Georgia; New Orleans, Louisiana; and parts of Florida—with more than a century of experience to help you through every stage of your business.

Our local team doesn’t just sell equipment—we help you every step of the way with site and contractor selection, equipment installation, parts support, warranty support and world-class customer service.

Partner With an Experienced, Trusted Distributor

Having the right team for laundromat and on-premises laundry solutions gives you peace of mind. When you partner with Alliance Distribution, you benefit from more than 100 years of experience in the laundry industry and global backing from Alliance Laundry Systems. Rely on expert service from our local distributors who know your business and region inside and out.

Our unmatched services include:

- Local in-house install crew

- Factory-trained, in-house technicians

- Genuine Parts replacement

- Full-service site selection, demographics, financing

- Store layout and design based on market

We don’t cut corners, we take care of our customers. When you work with us, you’re more than a customer—you’re a partner.

Connect with Us

Fill out the form below for your commercial laundry needs in the South Region.

UniMac® On-Premises Laundry Equipment is Built for the Toughest Loads

For industrial laundry equipment in the South Region, you can rely on UniMac’s unmatched durability when rugged equipment is an absolute requirement. Machines are backed by an exceptional warranty and the largest service and support network in the area.

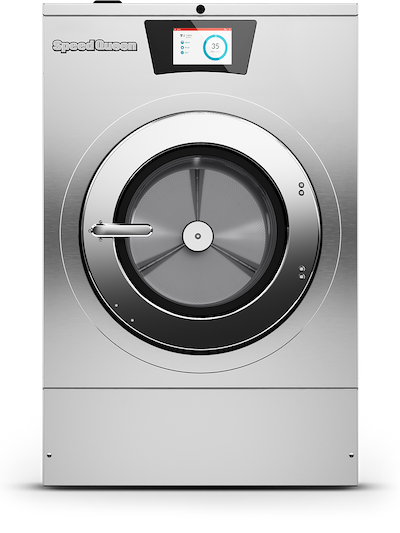

Speed Queen® Laundry

Machines for Apartments

Whether you’re a landlord with a few apartments or a property manager with hundreds of units, we’ve got you covered with Speed Queen laundry machines for apartments made with tougher parts to meet the challenges of unending loads. Made with metal parts—not plastic—American-quality machines are backed by the strongest warranties in the industry. Monitor machine performance remotely, offer reward incentives and provide convenient payment options.

Fast and Ready Service When You Need It Most

Service needs often happen when it’s least convenient. Don’t wait—our locally committed technicians for commercial laundry equipment (Houston and Dallas, Texas; Atlanta, Georgia; New Orleans, Louisiana; and parts of Florida) have the expertise and standard parts you need to get back up and running in no time.